Power Stroke® Reference Manuals Keep You In The Know.

If you're in the market for fuel injectors, make sure to read this important competitive comparison information. Choose genuine - drive with confidence.

Product Manuals. Power Stroke ® Reference Manuals Keep You In The Know. Remanufactured 6.0L Injector Comparisons. If you're in the market for fuel injectors, make sure to read this important competitive comparison information. 6.4 Power Stroke Diesel Engine Problems. The 6.4 Power Stroke only had a few short years in Ford trucks. It’s also the last Ford diesel from International as Ford designed and built the 6.7 Powerstroke in house. Ford 6.4 diesel engines make a solid 350hp and 650tq from the factory. Respectable numbers for the era the 6.4 Powerstroke was released.

- Completely rebuilt 6.4 power stroke turbo diesel-$8500 in the rebuild-ARP head Silver Clearcoat Metallic, 4WD, Manual, 5.40L V8, Truck. 2008 NEW FORD F 250 350 SUPER DUTY 6.0 6.4 POWER DIESEL (NO 2008 FORD F250 350 450 550 SUPER DUTY DIESEL OWNERS MANUAL BOOKS. 2008 Ford F350 Service Manual. S and very early 1960 one of the most.

- FORD POWERSTROKE 7.3,6.0,6.4,6.7 Engine Transmission 1/2 YEAR WARRANY $0 (FORD Truck Parts and Engine motor) pic hide this posting restore restore this posting $0.

Need a maintenance item or a replacement part for any current or past Power Stroke® Diesel engine. Make sure you get the right part, every time with our great reference manual.

Click here to download the PDF version of the catalog.

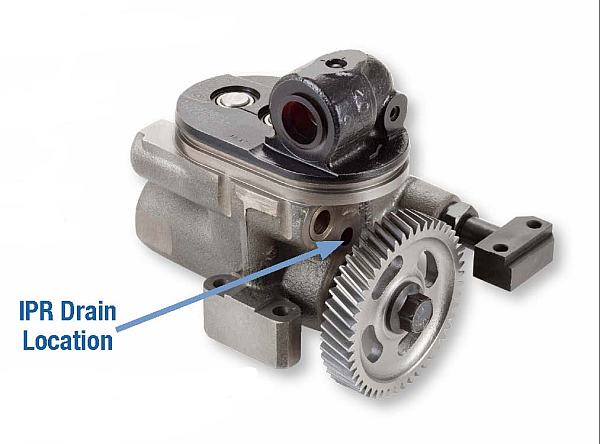

This reference aid is a great resource for technicians. Highlights include detailed 6.4L engine description, component location and technician tips.

This reference aid is a great resource for technicians. Highlights include detailed 6.0L engine description, component location and technician tips.

This reference aid is a great resource for technicians. Highlights include detailed 7.3L engine description, component location and technician tips.

Easy to use handbook that highlights commonly purchased parts for Model Year 2004-2011 F-650/F-750/LCF trucks. Guide includes part descriptions, Ford and/or Motorcraft part number, and the truck Model Year that the part is available.

This comprehensive, straightforward booklet features the top part numbers for major all-makes suppliers as well as a complete list of all-makes suppliers available through the Ford Commercial Truck Parts program.

After all the machining is performed, the engine can be reassembled in the reverse order that it was torn down.

Of course, I encourage you to follow traditional engine building practices. Clean all sealing surfaces before assembly and installation of any gaskets or sealant, and remember to lubricate all the engine’s internal moving parts and bearings during reassembly.

This Tech Tip is From the Full Book, HOW TO REBUILD FORD POWER STROKE DIESEL ENGINES 1994-2007. For a comprehensive guide on this entire subject you can visit this link:

LEARN MORE ABOUT THIS BOOK HERE

SHARE THIS ARTICLE: Please feel free to share this post on Facebook / Twitter / Google+ or any automotive Forums or blogs you read. You can use the social sharing buttons to the left, or copy and paste the website link: https://www.diyford.com/ford-power-stroke-engine-assembly-guide-step-step/

Step-1: Paint the Block

After machining and cleaning the block, mask off all of the internals of the block and paint the block. VHT Paints (a division of Duplicolor) offers a wide range of colors for a variety of applications. The paint is very durable and stands up to the high heat of Diesel components.

Step-2: Reinstall Galley Plugs

One of the critical things to do at this time is to make sure all of the galley plugs that were removed to clean the block passages are reinstalled.

Step-3: Install Cam Bearings

At this time, new cam bearings can be installed. When tearing down a Diesel you may notice that all the cam bearings look worn down to the copper layer of the bearing. This is normal and a lot of re-builders choose not to replace the cam bearings unless the engine was exposed to other detrimental issues.

Step-4: Prepare Oil Cooler Assembly

Take apart, clean, and re-seal the oil cooler. Take the time to paint the oil cooler with VHT paint also.

Crankshaft

Step-1: Check Bearing Clearances

In order to perform the proper rebuild, check the bearing clearances. Main bearing clearance should be somewhere between .002 to .0035 inch.

Step-2: Choose Engine Bearings (Torque Fasteners)

ACL bearings have provided quality bearings for the OEMs for more than 50 years. For the Power Stroke engine, ACL offers a Duraglide series, which is manufactured of copper, lead, and tin for heavy-duty service and wear.

Step-3: Install Piston Oilers

Before installing the crankshaft, make sure to install the piston oilers in the main webbing of the block. Apply Loctite 271 to the threads of the bolts to properly secure them.

Step-4: Install Crankshaft

Install the crankshaft and properly torque the main bearing bolts.

Pistons

These examples give you an idea of how much material on each end of the connecting rod was removed in order for the assembly to be balanced.

Step-1: Install Pistons on Rods

Lubricate the wrist pins with oil and assemble the pistons to the rods. Make sure to place the piston bowl toward the cam side for the 7.3.

Mahle pistons are provided with Perfect Circle rings. Perfect Circle has been manufacturing rings for heavyduty applications for more than 30 years. The top ring is barrel-faced for better seal and quicker breakin, the second ring is a reverse twist for better oil control, and the oil ring is chemically polished for better oil drainback and has a 20-degree gear angle to ensure side seal. All rings are packaged for their correct location on the piston.

Step-2: Inspect Ring Gap

Before installing the rings onto the pistons, take the time to make sure the rings are properly gapped for the application. Rings are packaged with information regarding the acceptable clearance.

Step-3: Verify Bearing Clearance

A cheap way to ensure the proper bearing clearance is to use an inside micrometer. This can be used to measure for proper bearing clearance.

Step-4: Install Pistons

Install the piston rings onto the piston and lightly oil them. Place the rings in the proper position on the piston and install the pistons in the bore with a piston ring squeezer.

Camshaft and Lifters

Step-1: Install Camshaft

Install the camshaft into the block and line up the marks on the camshaft with the crankshaft.

Step-2: Install Lifters and Hold-Downs

After the camshaft is installed and aligned with the crankshaft, the lifters and the lifter hold-downs can be installed in the block. Use Loctite 271 on the threads of the lifter hold-down bolts.

Cylinder Heads

Step-1: Reassemble Valvesprings

Luricate the valve stems with oil and insert the valves into the heads. Install new seals and reassemble the valvesprings.

Step-2: Select Head Bolts (Save Money)

A head bolt for the Power Stroke engine is called a “torque-to-yield” bolt. Once removed, factory bolts can no longer be reused. Over a period of time, these “torque-toyield” bolts fatigue and cause the head gasket to fail, especially on the 6.0. Instead of purchasing replacement head bolts and to ensure the maximum clamping load to the head gasket, I recommend the use of ARP head studs. ARP also manufactures bolts from the same quality of steel that is used in its studs for a wide variety of applications.

Step-3: Install Cylinder Heads and Pushrods

Install the cylinder heads and torque the studs to ARP recommendations. The studs do not torque the same as the factory head bolts. Once the heads are installed and properly torqued, install the pushrods.

Step-4: Install Rocker Arm Stand

Install the rocker arm stands onto the cylinder heads. Make sure to lubricate the rocker arm ball and pushrod with oil.

Step-5: Install Glow Plugs

Install the glow plugs into the cylinder heads making sure to coat the threads with Loctite (PN 77164) highnickel anti-seize lubricant.

Step-6: Install Plugs into Galley (Torque Fasteners)

At this time, install new plugs into the galley of the front and rear of the cylinder heads for the highpressure oil passages. These plugs need to be ordered from Ford (PN 4C3Z-6026-CA). Apply Loctite 271 to the threads and torque the plugs to 60 ft-lbs.

High-Pressure Oil Pump (HPOP)

Step-1: Install Gaskets

When installing the new gaskets onto the front cover, you will notice that there is a trough in the front cover that needs to be filled with a small amount of gasket sealer. After applying the sealer, install the front cover onto the front of the engine. The front cover of the engine was previously cleaned and then painted using VHT aluminum spray paint.

Step-2: Insert HPOP Gear

Insert the gear for the HPOP into the top of the front cover.

Step-3: Install HPOP

Install the HPOP in the back of the front cover while positioning the gear over the shaft of the pump.

Step-4: Install Drive Gear Bolt (Torque Fasteners)

Install the HPOP drive gear bolt through the front cover and thread into the HPOP. Torque the bolt t 90 ft-lbs.

Step-5: Install Reservoir

Insert a new gasket into the base of the HPOP reservoir and install the reservoir onto the top of the front cover.

6.4 Powerstroke Rebuild Manual

Oiling System

Step-1: Install Oil Cooler

After the exhaust manifolds were blasted, they were painted with high-heat cast-iron paint from VHT and secured to the block with new ARP stainless-steel bolts. The oil cooler can be installed at this time also.

Step-2: Install Oil Pump Gear

When installing a brand new oil pump from Ford, make sure that the word “OUT” is not facing the inside of the front cover as this picture represents. The word “OUT” on the pump needs to face the inside of the oil pump or damage to the front cover occurs.

Step-3: Install Galley Plug

Make sure the galley plug is installed in the rear of the block beside the camshaft before installing the rear cover.

Step-4: Clean Rear Cover

Clean the rear cover and apply sealer around the edges of the cover along the bolt holes. This is the only way to seal the rear cover; there is no gasket.

6.4 Powerstroke Rebuild Manual Master Cylinder

Step-5: Install Rear Seal (Special Tool)

The rear seal needs to be installed. This requires a special tool in order to install it with a wear sleeve. The tool can probably be leased from your nearest parts store. If you choose to purchase the tool from OTC, the price is around $700.

Step-6: Install Oil Pump Pick-Up Tube

The oil pump pickup tube can now be installed to the front cover.

Step-7: Install Oil Pump

Sealed Power makes a replacement oil pump for the 7.3 (PN 224- 43626).

Step-8: Install Gaskets

Gaskets for the 6.0 are notched in relation to were they go. This makes it easy to begin placing the gasket into the component.

Step-9: Install Oil Pan

Before installing the oil pan, there is a plug on the side of the oil pan that is used to insert the oil indicator tube. Remove the plug and install a new gasket, which consists of an O-ring. This needs to be purchased from Ford (PN 3C3Z-6753-AA). Next, the oil pan can be installed using RTV sealer. This is the only way to seal the pan on the 7.3. An oil pan gasket is only offered for the 6.0 engine.

Written by Bob McDonald and Republished with Permission of CarTech Inc

GET A DEAL ON THIS BOOK!

6.4 Powerstroke Rebuild Manual Diagram

If you liked this article you will LOVE the full book. Click the button below and we will send you an exclusive deal on this book.